Defect detection procedure for molecular filters

Acetone is a solvent that evaporates easily and quickly at room temperature; it is a good tracer for estimating the level of defect in molecular filters. This procedure presents two methods for evaluating defects in activated carbon filters. After evaporating a small amount of acetone inside the device, either an acetone detection tube or a PID detector can be used. This allows you to determine whether a filter replacement is necessary.

Filter defect detection using colorimetric tubes

Required equipment list:

- Approximately 5 ml of acetone (not provided)

- Absorbent paper (not provided)

- Dish or crucible (not provided)

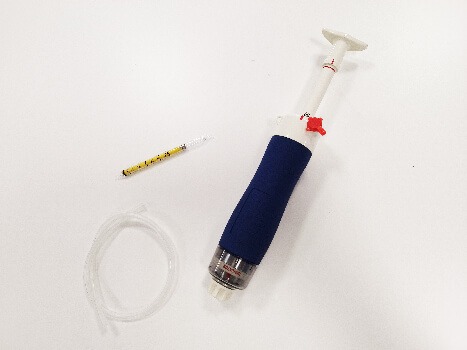

- Tygon tubing (provided). Do not use other materials, such as silicone, which may adsorb acetone and distort the measurement

- Sampling pump (not provided)

- Colorimetric tube (not provided)

The list of equipment not supplied by Erlab can be purchased from various manufacturers such as Gastec, Draeger, RAE System or their authorized distributors.

Always use a pump and tube of the same brand.

Gastec tube ref.: 151 L (2 pump strokes)

Drager tube ref.: 81 03 381 (1 pump stroke)

RAE tube ref.: 10-111-40 (100cc to be sampled)

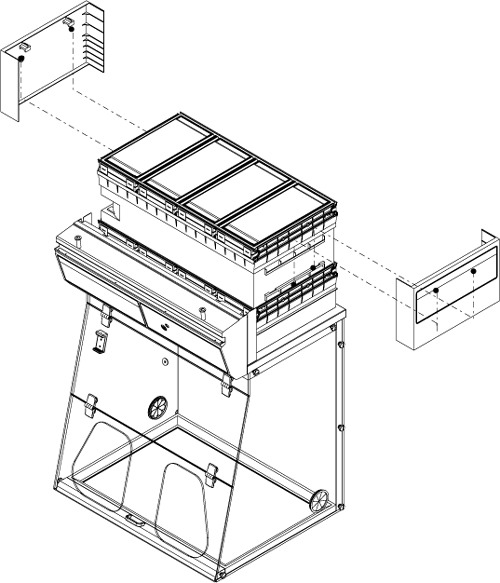

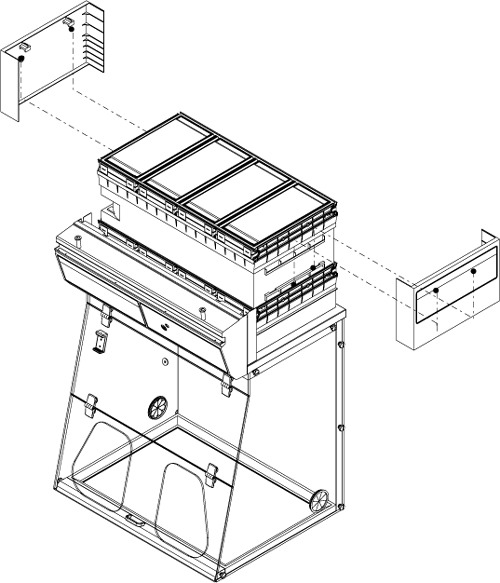

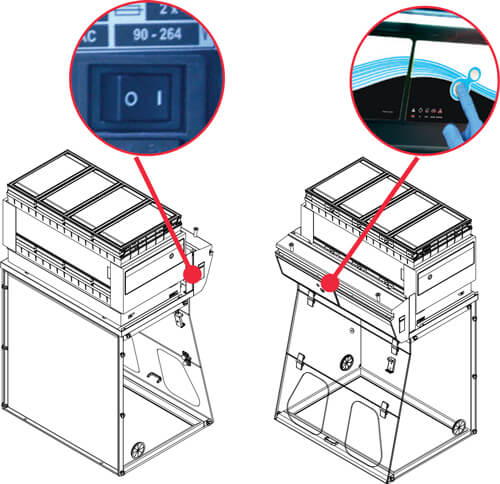

Remove the protective covers, only for fume hoods and cabinets.

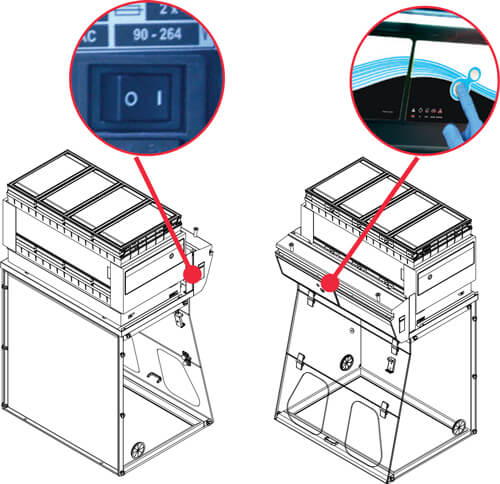

Switch on the hood and cabinet, then start the ventilation.

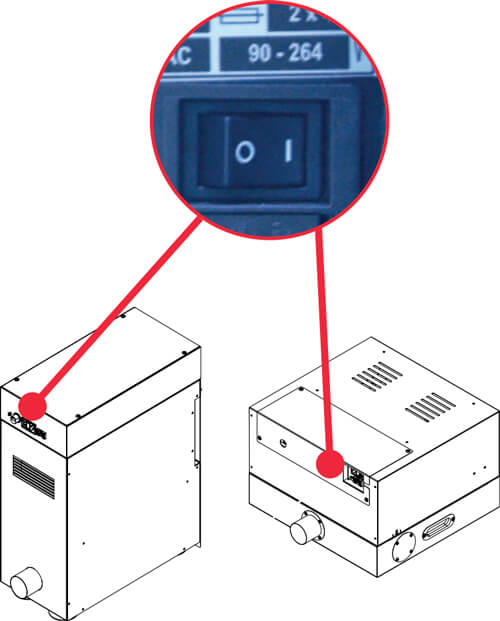

Switch on the Chemtrap H and V, the ventilation will start.

Soak a paper roll placed inside a container located within your hood, cabinet, or safety cabinet.

5 ml of acetone (min 98%) per filtration column.

For example, for a device with 3 filtration columns (Captair 483), soak 15 ml of acetone on absorbent paper.

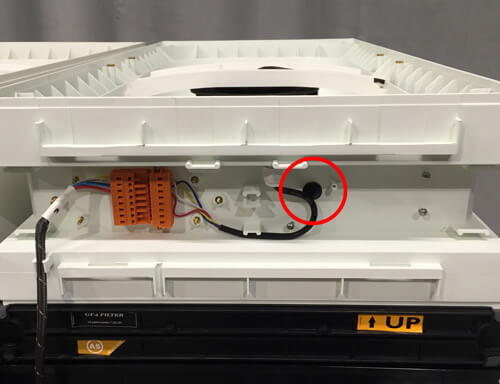

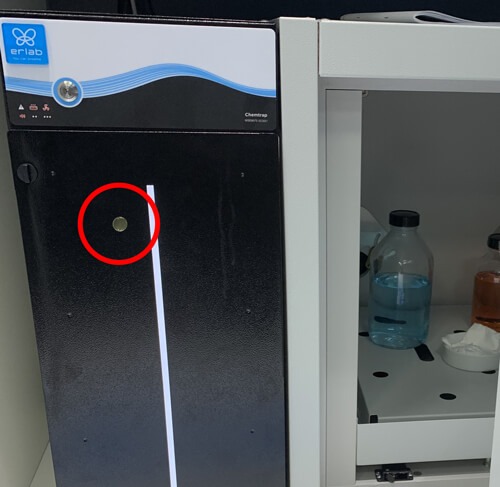

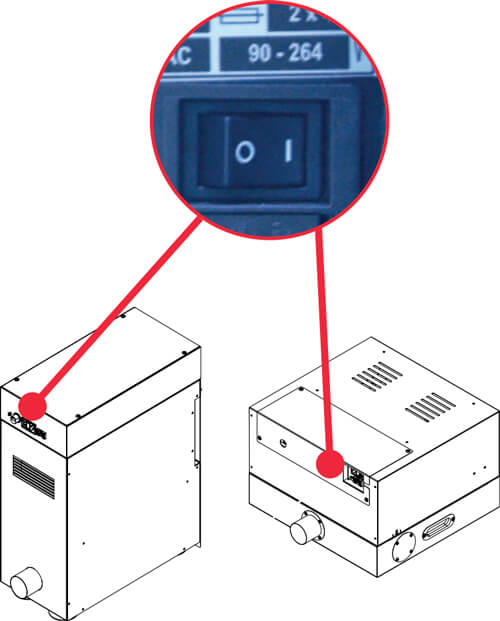

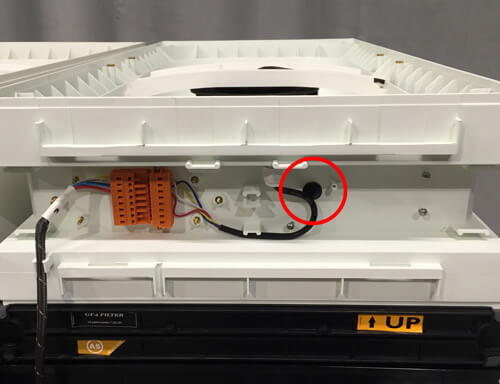

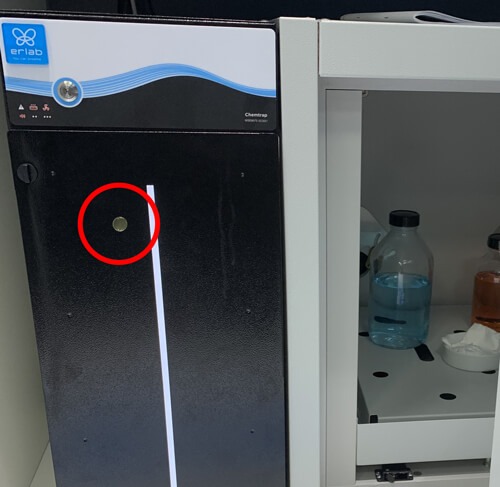

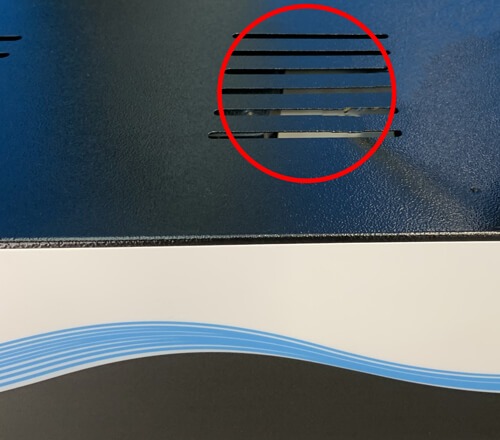

After removing the cap from the sampling port, connect the tubing to the ventilation module.

After removing the cap from the sampling port, connect the tubing to the ventilation module.

Connect the tubing to the ventilation module.

Break off both ends of the colorimetric tube. Each pump is usually equipped with a tool for safely breaking the tube.

Connect the broken tube to the pump, ensuring it is inserted in the correct direction. Colorimetric tubes are marked accordingly.

- Proceed with aspiration through the colorimetric tube. Check the number of pump strokes required as indicated by the manufacturer.

- If the detection threshold of the tube is exceeded, proceed with changing the filter(s).

Filter defect detection using PID detector

Required equipment list:

- Approximately 5 ml of acetone (not provided)

- Absorbent paper (not provided)

- Dish or crucible (not provided)

- Tygon tubing (provided). Do not use other materials, such as silicone, which may adsorb acetone and distort the measurement

- PID detector (not provided).

The list of equipment not supplied by Erlab can be purchased from various manufacturers such as RAE System or their authorized distributors.

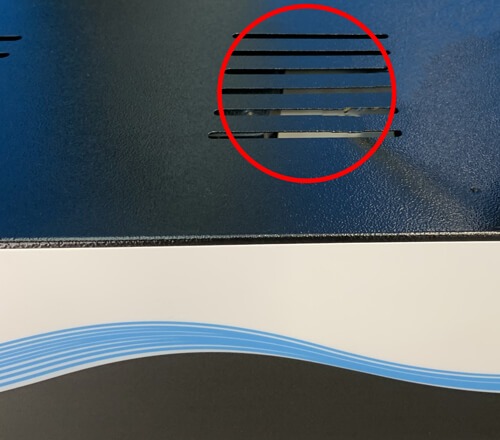

Remove the protective covers, only for fume hoods and cabinets.

Switch on the device, then start the ventilation.

Switch on the Chemtrap H and V, the ventilation will start.

Soak a paper roll placed inside a container located within your hood, cabinet, or safety cabinet.

5 ml of acetone (min 98%) per filtration column.

For example, for a device with 3 filtration columns (Captair 483), soak 15 ml of acetone on absorbent paper.

After removing the cap from the sampling port, connect the tubing to the ventilation module.

After removing the cap from the sampling port, connect the tubing to the ventilation module.

Connect the tubing to the ventilation module.

- Connect the end of the TYGON tubing to the PID detector's sampling inlet

- Select the target gas 'Acetone' from the PID menu (refer to the user manual if necessary)

- If the PID detector shows a concentration above 5 ppm, proceed with changing the filter(s).